Buyer Beware

Stainless Steel is Not all the Same. Stainless is used for many Products and in the Home you see it mostly in the Appliances, Sinks and Cookware.

Stainless Steel has a Reputation of High Quality, Durability and Longevity that could be Negatively affected by improper use of Certain Grades not Suitable for their Purpose.

Promoting a Product using 200 or 201 Series Stainless, that has less Chromium, for use in a Corrosive Applications Such as a Sink or Cookware will not Perform as expected. A minimum of 10.5% Chromium by weight is required to be considered Stainless Steel.

Cookware

Stainless Pots & Pans for some is the only Metal Container they Trust for Cooking without the Risk of Toxic Fumes or Contaminates at High Temperatures.

Stainless Cookware is Safe, Durable and Scratch Resistant. Possible Chemical Migration from Stainless Steel is Zero.

Magnetic and Non Magnetic is Important if you have or are Planning on a Induction Cooktop. Most Stainless Steel for Cookware contains between 8% & 20% Nickel which is Non-Magnetic and will Not Work on Induction Cooktops.

Some Stainless used for Cookware Does Not contain Nickel and is Magnetic. Cookware Makers now use this Icon indicating their Cookware is Compatible with Induction Cooking. See our Article "Induction Cooktops" in Link below.

Heat Transfer is Measured in a Thermal Conductivity Coefficient or How Evenly the Pan Heats Up. Stainless Steel is Considered a Poor Conductor of heat with a Coefficient of 25, while Copper is 386 and Aluminum is 239 the Higher the Number the Better Heat Conductivity.

Higher Quality Stainless Cookware can be 3 Ply Construction. The Pan itself would be a 324 Series Stainless sometimes referred to as 18/8 or 18/10.

The Heavy Bottom is a layer of higher Conductive Copper or Aluminum sandwiched in between the 324 and the Bottom is a Magnetic Layer of 430 or 440 Stainless.

The 310 & 316 Higher Grade Stainless is more Resistant to what you may be Cooking, but they are Typically used where Welding is required.

The 430 & 440 Series Stainless do not have Nickel making it Magnetic, a Perfect Solution For Induction Cooktops.

Sinks

Stainless Steel Manufacturing to my knowledge does not have a International Regulatory Agency monitoring the Production Standards of Stainless Steel.

ASTM an Organization with Open Membership but not Mandatory Publishes Technical Standards for a variety of Products including Stainless Steel. The Specifications for the Kind and Quality of Stainless used in Sink Production is determined by the Sink Manufacturer.

Stainless Sinks and other Stainless Products are Rarely Marketed using their Grade of Stainless as a Selling Point. Sinks are Typically Made of 324, 316 and 316L, using our Chart you can see the difference in all three.

The Majority of Stainless Sinks are Stamped out in a Press like a Car Fender. The Stainless is Purchased from the Steel Manufacture, mostly in Big Rolls, made to Certain Specifications.

Formation by Pressing requires certain Formability of the Stainless and also maintain a level of Corrosion Resistance for its use.

Appliances

300 Series Stainless Steel is widely used for Appliances, more specifically 324 18/8 or 18/10. 324 Stainless has Increased Strength and Increased Corrosion Resistance by adding Nitrogen and reducing Carbon.

Uses like Refrigerator & Dishwasher Doors and Ranges. Dishwasher Interiors using Stainless Steel should have Stainless Capable of handling Food Acids at a Higher Temperature.

An important Consideration when Purchasing Stainless Steel Appliances is the Finish. Manufactures do not have the Same Finishes, KitchenAid® is not the same as LG® or Samsung®.

Refrigerator Doors have the Largest amount of Visible Stainless and if you choose 2 or 3 Separate Manufactures for your Appliances you will have 3 different appearing Finishes that Do Not Match.

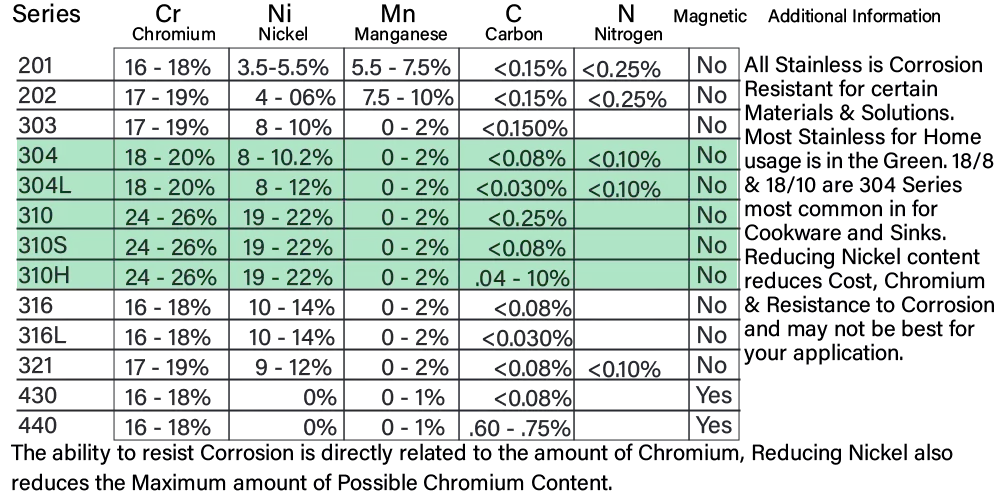

Stainless Chart

Chart Disclaimer. The information is this Chart is for Informational use for a reader to have a Basic Understanding of the Ingredients in Various Stainless Steels. The Chart Specifics should not be Relied on and does not include all Stainless Steel Available.

Comment Below

Internal Links

Like this Article, you can give us a Thumbs just click on the Icon. It's anonymous and we will Thank You.

“No man becomes Rich unless he Enriches Others”

Andrew Carnegie

Additional Information

The following is an Explanation of the Ingredients in Stainless Steel

Chromium (Cr)

Chromium is the Critical Part of Stainless Steel that takes a High Polish. Chromium Hardens, Toughens and Increases its Resistance to Corrosion Particularly at Higher Temperatures. Chromium is what makes Stainless Steel "Stainless".

Chromium resists Corrosion by forming thin layer of Chromium Oxide over the Surface called the "Passive Layer" this layer of Protection can in many cases repair Damaged Areas on the Surface.

The ability to resist Corrosion is directly related to the amount of Chromium, Reducing Nickel also reduces the Maximum amount of Possible Chromium Content.

Nickel (Ni)

Nickel is used in nearly 75% of Stainless Steel Production, Series 430 Stainless does not contain any amounts of Nickel.

Nickel is non magnetic and adds to the increase Corrosion Resistant of Stainless Steel. Nickel plays an important role in Strength. Chromium reduces the Strength and the Addition of Nickel makes up for it.

Manganese (Mn)

Manganese is added to Stainless mostly as a Substitute for Nickel. You can see in the Chart where 201 & 202 Stainless have smaller amounts of Nickel and Increased amounts of Manganese. This Substitution was an effort to reduce the use of Nickel during War Times. Today the Price of Stainless is most affected by the Nickel in Stainless. Reducing Nickel then increasing Manganese makes Stainless more Economical and less Corrosion Resistant.

Carbon (C)

Carbon is in Stainless Steel but very small percentages, Carbon Strengthens Steel. High Carbon content in Stainless Steel does inhibit Welding due to Carbide Precipitation. Welding Stainless for some applications like Sinks and Appliances should be 316L (less Carbon). High Carbon Stainless is used mostly in Cutlery and High End Knifes.

Titanium (Ti)

Titanium is added to Stainless Steel as a Carbide Stabilizer when Welding is used.

Molybdenum (Mo)

Molybdenum is added to Stainless Steel to increase the Resistance to Pitting and Crevice Corrosion where Welding is required. Used mostly where Liquids will be in contact with the Stainless, like Sinks and Marine Applications.MO is added to 316 & 316L 2 - 3%

Nitrogen (N)

Adding Nitrogen and lowering Carbon has the affect of stabilizing Austenitic Stainless, and increases the Resistance to corrosion by Pitting.

© Copyright 2023 YPRemodel.com. All rights Reserved. This material may not be Published, Broadcast, Rewritten or Redistributed without written Permission.