>

>

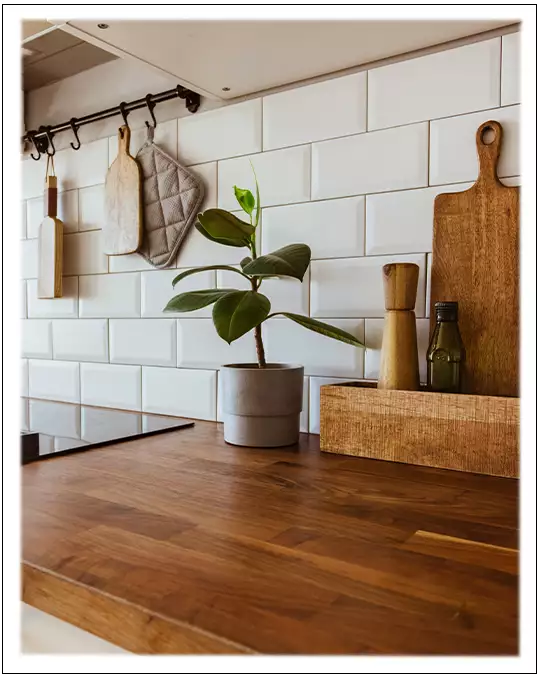

Are Butcher Block Countertops Returning?

Yes, BUT, Today's Butcher Block Countertops are not the Same Ones from the 70's, Exotic Wood, Wider & Less Contrasting Planks. Over the Past 7 decades we have experienced the changes in Trends for Countertop Materials. Butcher Block Tops, Printed on Formica® came along in the Early Part of the 70's it slowly gave way to Corian® and Ceramic Tile in the 80's.

Saying they are making a Full Return or will be Replacing Solid Surface, isn't True. Some say the Trend is One very Nicely Done Wood Surface Island with Hard Surface on the rest.

Butcher Block Tops may not be a Cheap or an Economical way to Replace any of your Kitchen or Bath Countertops. If you are considering this as a DIY Project, Great. Be Prepared for Expensive Wood Prices when you go to your Specialty Wood Supplier. We listed some Prices but with Inflation and Supply Shortages the Prices could be much Higher.

Material

Material needed for a Wood Top like this is not available at a Big Box Store. In the Phoenix area we are lucky to have Several Specialty Wood Stores available. You can use your choice of Hardwood, Cherry would be my Pick depending on the Final Cost of all the Boards needed.

The Layout

Real Wood Butcher Block Tops are Constructed by placing Long Strips of Wood, typically 1 1/2 up to 2 1/4 inches Thick, side to side Face Grain up. A wide Board may give you 1, 2 or 3 Strips you can put them together or move them around for a more Distinct Look. * Alternative, an Un-Tested method suggested by a Reader is Described at the End of this Article.

Using a 1 1/2 inch Thick Board is 7/32" Thicker or Higher, then a 2cm Hard Surface Countertop. Cabinet Height is 34 1/2" add a 3cm(1 3/16") Top equals 35 11/16" around 36" is Normal. Custom Bold Looking Tops should be 2 to 2 3/8 inches thick putting your Finished Height at 36 1/2" to 36 7/8".

Choose Long Boards if possible the Length can be extended using Finger Joints, Pocket Screws, Biscuits, Dowels, Half LAP or Spline Joints. Be careful not to squeeze out all the Glue and use a Straight Edge so the Glued Assembly is Perfectly Straight.

The Glue up

The Glue should be Food Grade and FDA (Food and Drug Administration) Compliant meeting or exceeding the Requirements for Indirect Contact with Food. In Addition the Glue must be Resistant to Water and Cleaning Fluids. Some Glues will release their Bond when exposed to Moisture.

Edging

Edging is a Personal Choice. If you have other Hard Surface Tops maybe Match the Edging. If you are going for a Full Disconnection of Style from the rest of the Tops and are using Ornate Legs at the corners then Maybe an Ogee with Bottom Bull Nose or without the Bullnose, Eased 1/8" to 1/2" Round over or Cove and Bead. All good Choices.

Top Coat or Sealer

You should not plan on using your Butcher Block Countertop to Chop or Cut on, Treat them like you would a Hard Stone Surface, Granite, Quartz and Quartzite. The Top Coat must be a FDA approved Food Grade Product and Water Resistant.

Not all of the 1st Coat Seals or Finish will allow you to change to a Different base Type, if you didn't like your 1st choice. For Example a Rubbed Oil Finish will not accept a Paint or Polyurethane because the Oil Penetrates deep into the Wood and may not allow the Polyurethane to Bind to the Material. This also True in the Reverse, Polyurethane could Prevent Oil from Penetrating down into the Wood.

Chose the Finish depending on the Tops Use and Abuse plus the Finished Look you want. If the Top is an Island then I would Choose a Polyurethane used for Floors. If you want an Oil Appearance then use an Oil. Oil will require resealing more often than the Poly. Also Seal or Oil the Bottom to Prevent Drying Out.

Like this Article, you can give us a Thumbs just click on the Icon. It's anonymous and we will Thank You.

“The Shadow is what we think of it; the tree is the real thing”

Abraham Lincoln

Cost Example

Examples of Pricing for other Species that could be used for Countertops. Quarters is the Thickness, e.g., 4 Quarters (4/4) is 1" Thick, 6/4 is 1 1/2", 8/4 is 2", then 12/4 is 3".

- Cherry - 6/4 $8.50/bf - 8/4 $9.00/bf

- Alder 6/4 $8.20/bf - 8/4 $8.50/bf

- Hard Maple - 6/4 $10.50/bf - 8/4 $11.00/bf

- Premium Walnut - 6/4 $19.00/bf - 8/4 $20.00/bf - 12/4 $21.00/bf

- Widths Vary no Standard Width Boards, you are able to pick & choose each Board for yourself

Let's say you want to build a Top with Walnut, 108" long by 44" wide 3cm thick, that is 66bf (Board Feet). 66bf X's $20.00/bf = $1,320.00 just for the Wood, a Very Nice Wood. This Formula uses a 8/4 Board that you can run through the Planer for the Desired Thickness. You could use a 6/4 Board if 2cm if your Finished Thickness. The Widths will vary, you are able to pick & choose each Board for yourself.

The Un-Tried Method from a Reader

A Method for a more economical way to Construct a Exotic Wood Countertop with 4/4 Wood Stock. After your Boards have been Planed, Straight Edged and because the Boards are so Thin use the Router to cut Tongue and Groove Edges or Use a Rabbet Tongue and corresponding Cut to the Joining Board.

Use a 3/4 Sheet of MDF to Glue your Planks to making Sure Each Joint is Sealed with the Proper Glue so Moisture cannot get to the MDF. The MDF will serve as the Substrate. You would have to attach a Vertical Board on the Parameter which gets Your Edging Choice using a Router.

The Outside Board Could be as Tall as you want just be sure to compensate from under so the Drawers & Doors open 2" would look Good. Unfortunately it will only save about $140.00 Some of my Wood Worker Friends think it could be an easier way to build it as long as the Moisture doesn't get to the MDF.

© Copyright 2023 YPRemodel.com. All rights Reserved. This material may not be Published, Broadcast, Rewritten or Redistributed without written Permission.