Door Styles

Shaker

This Style of Cabinet Door has been around since the early 1800's a Simple or Minimalist Design started by a Religious Group, who were referred to as Shakers in New York and the New England area.

A modern Shaker Style Kitchen Cabinet is Simple without Mitered Corner Joints, Just Styles (left & Right Sides) and Rails (Top and Bottom) using the Mortise and Tenon Style Joint with a Recessed Center Panel.

The Center Panel is Typically a 1/4" to 3/8" piece of Engineered Wood, This Simple and appealing Look is Timeless, always in Style and blends easily with other Design Styles.

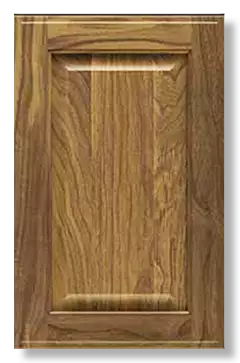

Traditional Raised Panel

Raised Panel Cabinet Doors have been a Style associated with a Traditional Kitchen using High Quality Stained Wood. A Kitchen with Raised Panel Doors is more Decorative, Detailed, or Dignified.

The Raised Panel Cabinet Door is a 5 Piece Construction. The Joints and be Mitered or Set at 90 degrees. see description below

Reversed Raised Panel

Reversed Raised Panel Door is used to make the Door more Robust or Solid. It can be a Shaker Style but the Heavier Raised Panel that is set in with the Flat Side Showing changes the Feel and Sound of the Door.

The Reversed Raised Panel is typically made of a Solid Wood Product not a Manufactured Wood Product. The Raised portion of the Panel doesn't have to be Ornate or Decorative is just needs to be thicker than a Normal Panel to give the Door that Solid Feel.

Contemporary

Contemporary Designed Kitchens have a Flat Panel High Gloss Door, no Curves just a Straight Geometric Design. Hidden Hinges and Hidden Handles Simple and Modern. The Slab Type Doors can be a High Gloss Laminate over MDF. The Door is Heavy and Stable but will not take abuse like running the Vacuum into the edge of a Door.

Inset Door Style

The Inset Door Style adds a very Clean Look to the Cabinet. The Door and Drawer are surrounded by the Face Frame that is normally behind the Door and Drawer. You can use an exposed door hinge on the Inset Style.

Mullion Doors

A mullion is a cabinet door that is composed of glass panes. The glass panels have dividing bars similar to those found in window panes. They are used as a Decrotive look in the Kitchen to Display Dishes or any type of Dinnerware.

Wood used for Doors

Most if not all Cabinet Manufactures use these common Hardwoods in the Construction of Cabinet Doors. Price Range is going to determine the Kind of Wood with Most.

The 5 most common are Maple, Cherry, Alder, Walnut and Oak. Oak is available in Straight Sawn and Quarter Sawn. To learn more about Oak see or Article "Hardwoods used for Cabinets (link below).

Cost of Material and the Difficulty required to Process the Lumber into the Pieces needed for the Doors will affect the Final Price.

If the Cabinets are going to be Painted with your Color Choice, the Styles and Rails will most likely will be Maple and the Center Panel if Shaker Style could be Plywood or MDF for Stability.

Reversed Raised Panel Doors may use Maple on the Center Panel also. If the Reversed Raised Panel is going to be Stained then all five pieces of the Door will be the same kind of Wood.

Thermofoil is another Option for Kitchen and Bath Cabinet Doors. This is a MDF Material, see our Article Manufactured Woods for an Explanation of MDF (link below).

The Surface of Thermofoil Doors uses a Vinyl or Plastic Material that is Heat Fused on to the MDF. The Finish would be similar to Melamine. The Finish can be alomost any Color that will make an outstanding Looking Door for an Attractive Price.

Finishes

Stains on Hardwoods enhance the Natural Beauty of any Wood. The Color and Deepness of a Stain can bring out the Woods Character. Lighter Stains allow more of the Graining to Show, and the Darker Stains tend to hide some of the Grains.

Painting, some Manufactures use the name Opaque for the Painted Finish, Paint or Opaque they are available in many Colors. Standard Colors vary between Manufactures but most will Custom Color for You. I am not sure how many Manufactures use the UV Curing Process on their Painted Cabinets but the Process provides a Hard, Durable and Long Lasting Finish.

Painted Cabinets especially White are a very Popular Finish for Kitchen and Bath Cabinets. Most Cabinet Manufactures add a Up charge to Cabinets when Painted, it could be as High as 15%.

Joints

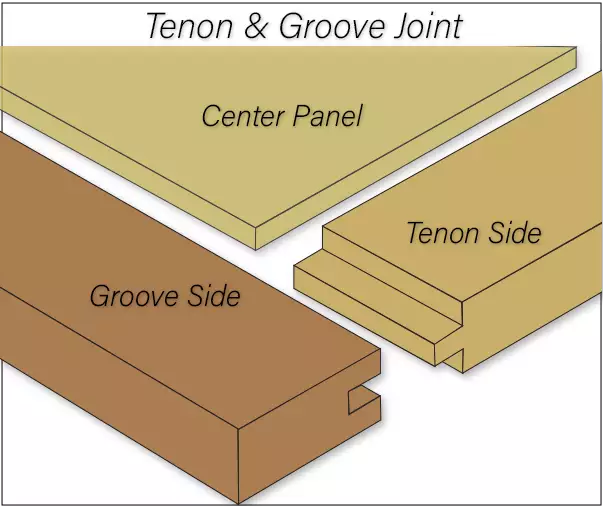

The Shaker Style Cabinet Door use 2 Styles & 2 Rails each with a width of 1 3/4" to 2 1/2". The Rails (top and bottom) fit inside the Styles. The most common Joint used for the Shaker Door Construction is the Mortise and Tenon Style Joint.

As you can see in the Image The Tenon fits inside the Groove that is cut is in all the Styles and Rails, the Door Center Panel also fits in the Groove.

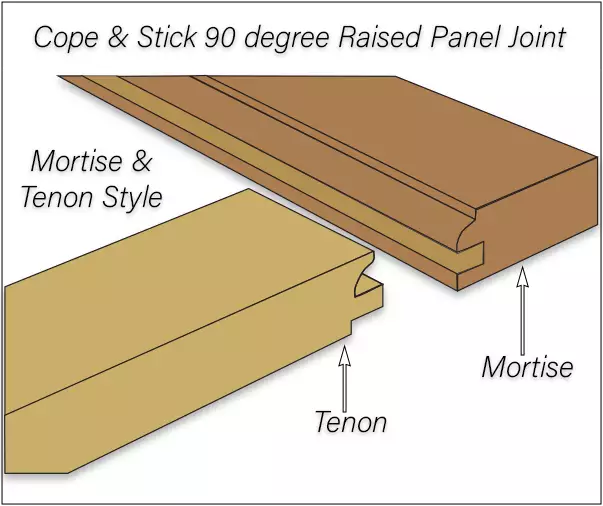

The Raised Panel Cabinet Door uses a 5 Piece Construction, the Cope and Stick Style of a Mortise and Tenon, 90 degree Joint. The inside of the Styles and Rails are Machined with a Decorative inside Edge. The 4 Corners are assembled at 90 degrees with the Center Panel inside.

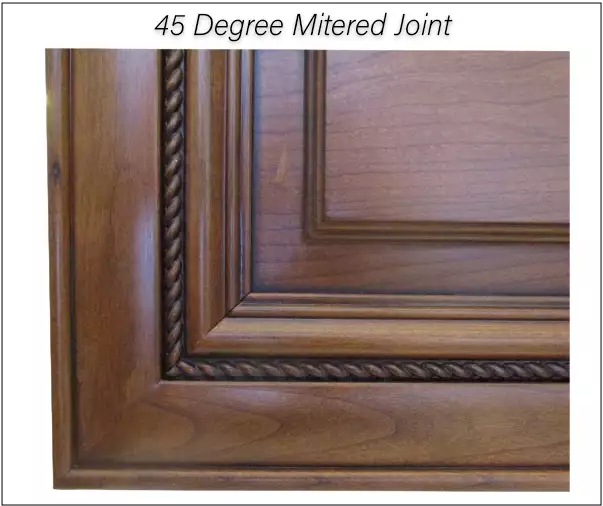

The Raised Panel and Reversed Raised Panel Cabinet Door, 5 Piece Construction can also have 45 degree Mitered Joints. The Mitered Look is preferred by many because the Decorative Lines continue around the Door for a Clean overall Look. This is a Personal Preference, keep in mind that in some Locations the Joints may open more than you would like.

Hinges

Hinges normally open at 110 degrees, the Hinge is not seen when the door is closed and they are adjustable.

Soft close Hinges are preferred by most, although they are in some cases an Upgrade so they cost a little more. Soft Close Hinges improve the Movement when opening and closing of the Door. They allow for a Slow, Quiet and Graceful Closing Movement that prevents Slamming.

The Question regarding the Longevity of the Soft Close compared to the Regular Cabinet Door Hinge. Most would say that the Soft Close Hinge will last as long as a Regular Door Hinge. There are many factors that should be considered like Inexpensive Hinges, Overuse and Abuse.

Like this Article, you can give us a Thumbs just click on the Icon. It's anonymous and we will Thank You.

“Details matter. It's worth waiting to get it right”

Steve Jobs

© Copyright 2023 YPRemodel.com. All rights Reserved. This material may not be Published, Broadcast, Rewritten or Redistributed without written Permission.