About Hardwoods

Hardwoods most commonly used for Cabinet Construction like Maple, Cherry, Alder, Walnut or Oak don't even make the Top Ten Hardwoods in the World.

Maple and Oak are the 2 Hardest of the 5, and the other 3 are considered a Soft Wood. Any Wood with a Janka Scale Value of less than 1000 is considered a Soft Wood.

What is the Janka Scale

The Janka Scale developed by an Austrian Wood Researcher, Gabriel Janka in 1906. A Scale using Numbers between 0 (soft) to 4000 (Hard). The Test or Procedure is to determine the amount of Force it takes to embed a .444-inch Steel Ball half way into a piece of Wood.

The Test is the determine the Density, Resistance to Dings, and Dents thus the Wear ability of a Type of Wood. I might add the Ability to Hold a Screw or Nail.

Examples of Soft Wood

Popular Soft Woods are Douglas Fir, Ponderosa Pine, Yellow Pine, Red Cedar and Redwood.

Maple

Maple has a Fine Uniform Straight Grain. The color is light but will, as most Hardwoods, darken over time from UV Sunlight. As for Staining, Maple's Porosity prevents it from absorbing Stain well, use a Conditioner first.

Maple is a Close Grain Wood from a Deciduous Tree (lose their Leaves) in the Fall. Maple Trees are abundent in the Western Part of New York, the North Eastern US, including Canada.

The Beautiful Colors come from their Exposure to the Sun or Shade, Red in the Sun and Yellow in the shade plus some Genetics. It is said that they change Color by the Hour.

The Sugar Maple has a Hardness Value (janka value) of 1,450 in the Furniture Making Industry. Because of Maples Hardness, it is a little harder to work with like Cutting and Drilling. Sugar Maple's Hardness does not stop it from Scratches and Dents.

Maple is used for Furniture, Flooring Baseball Bats and other General Construction Projects.

Painting Hard Maple requires a slow dry Paint that has time to adhere to the wood. Maple is enduring, Local and Sustainable. The Grains and Colors of Hardwoods are part of the appearance you want. The Strength of Maple will give you the longevity you need.

Cherry

Cherry also has a Fine Uniform Straight Unpronounced Grain with a very Smooth Texture. As with most of the Hardwoods Cherry will also darker over time some say more than other Hardwoods. The darkness changes the most in the first couple of years.

North American Cherry Wood has a Hardness Value (janka value) of 995 in the Furniture Making Industry. The Softer Value makes Cherry Wood is Easy to Work with, it will Scratch and Dent Easier than Maple.

The Color is not Red as you can see in the Image below. Cherry Wood is a Smooth Close Grain that is not always the same in a Single Board depending on what part of the Tree it was cut from.

Cherry should have a Conditioner Applied before Staining to help absorb evenly. Cherry can be Stained with many colors to achieve the look you want. I cannot Imagine anyone wanting to Paint Cherry Wood.

Alder

Alder the softest of the Hardwoods. Alder is White in Color to Light Brown with a Yellow hue. Alder has a straight Grain appearance, that could be passed off as Cherry or Maple.

Alder's Rating on the Janka value is 590 a Soft Hardwood. Alder has a Medium Density it is Strong, Stiff, Shock Resistance and Light Weight. Alder has the reverse action when it comes to aging, the color or Shade will actually Mellow or Lighten over time.

Alder does not take Stain without first Applying a Wood Conditioner to help Absorb the Stain more Evenly. As far as Dents and Scratches, it is Soft Wood and you should Expect them.

If you Like the Look of Cherry but not the Price, Alder is a very Good Alternative. Alder Wood has a relative short Growth Cycle and is well managed in the Pacific North West. Alder is Abundant and readily Available.

Walnut

Walnut to me always appears as a Dark Chocolate Color, the Naturally Dark Part of the Walnut Tree is only in the Heart. As the Tree Grows the Heart is surrounded by the Sap Wood that is Lighter in its Natural Color.

Walnut Wood, a Very Dark and Elegant Wood, with hardness value of 1010 Hardness rating (janka value) putting it just above the Cherry Species.

Typical Hardwood darkens with age, Walnut is just the opposite it tends to get a little lighter with age. The Grain Pattern of Walnut is Wave Like Straight Grain. As for Staining, it is mostly Clear Coated, if Stained it would be to bring out the Dark Character of the Wood.

Walnut Trees grow slow, trees that can be Harvested are at least 100 years old. They grow best in States like Indiana, Illinois, Ohio.

Solid Walnut is available and because of their Slow Growth the Best use of the Wood is mostly as a Veneered Product like Plywood to get the look at a affordable Price.

In Cabinet use the Stiles and Rails would be Solid and the Center Panel would be a Veneer.

Oak

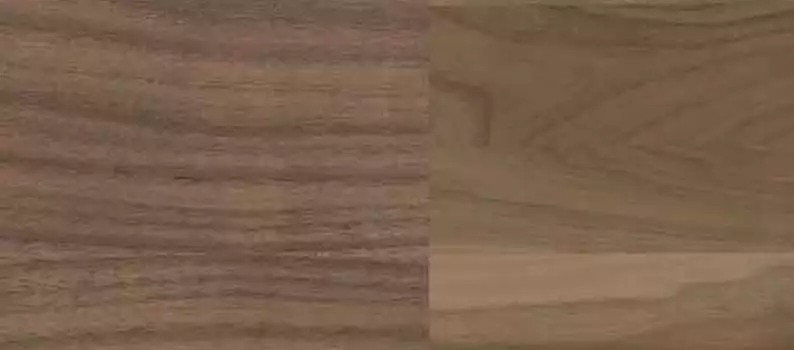

In this Oak Sample the Board on the left is a Straight Sawn Board and on the Right is a Quarter Sawn Board showing two Distinct Grain Patterns.

Oak has a value of 1360 Hardness rating (janka value) putting it just below the Sugar Maple Species. White and Red Oak are the 2 most common Varieties we see. There are around 60 different Species of Oak in the US and more than 600 World Wide. An Oak Tree is 30 to 40 years Old when Harvested for Lumber.

Oak Wood a Very popular Wood for many uses in Furniture, Cabinets, Flooring and is an excellent Wood for Barrels used for making Liquor and Wine. Baseball Bats in the early days were Oak, Durable but Heavy.

Oak is easy to work with Cuts, Drills, Sands and Stains well. Oak has a Straight Grain and Uneven Texture that makes it difficult to Paint to a Smooth even Finish. Oak is considered the least expensive of our 5 Hardwoods.

Cutting an Oak Tree for Quarter Sawn Boards. First the Log is cut into 4 quarters in the Long direction. Each Quarter is then cut Separately taking the 1st Cut off of the flat side, the log is turned 90 degrees so the next cut is from the other flat side. The Log is turned back and forth cutting from the Flat sides to the last cut. This Process is time consuming which makes Quarter Sawn Oak more expensive.

Like this Article, you can give us a Thumbs just click on the Icon. It's anonymous and we will Thank You.

“For in the true nature of things, if we rightly consider, every green tree is far more glorious than if it were made of gold and silver”

Martin Luther King Jr

© Copyright 2023 YPRemodel.com. All rights Reserved. This material may not be Published, Broadcast, Rewritten or Redistributed without written Permission.